![]()

(818) 928-1060

|

PRODUCTS for Every Need |

|

Business

Forms Checks & Security Printing Media Labels (for Operations) Labels (Prime for Products) Labels (Blank Stock ) Equipment Marketing /Sales Literature Stationery & Envelopes ID & Phone Cards |

|

SERVICES for Every Need |

|

Design Services Warehousing & Logistics Mailing & Fulfillment On-Line Capabilities Company Store Print Buying Project Management Data Mgmt/Re-Purposing Label & Tag Imprinting |

| RESOURCES & SUPPORT |

|

Color (CMYK vs. RGB) Software Downloads Barcode Tips & Symbology Omega Forms & Documents Print News / Quik Links Printing Industry Trade Customs |

| ABOUT US |

|

What makes us unique Why Choose Omega How to Contact Omega What Types of Businesses Work with Omega

Did you know in 2007 Omega was the

Learn how we may |

Label Manufacturing Presses

|

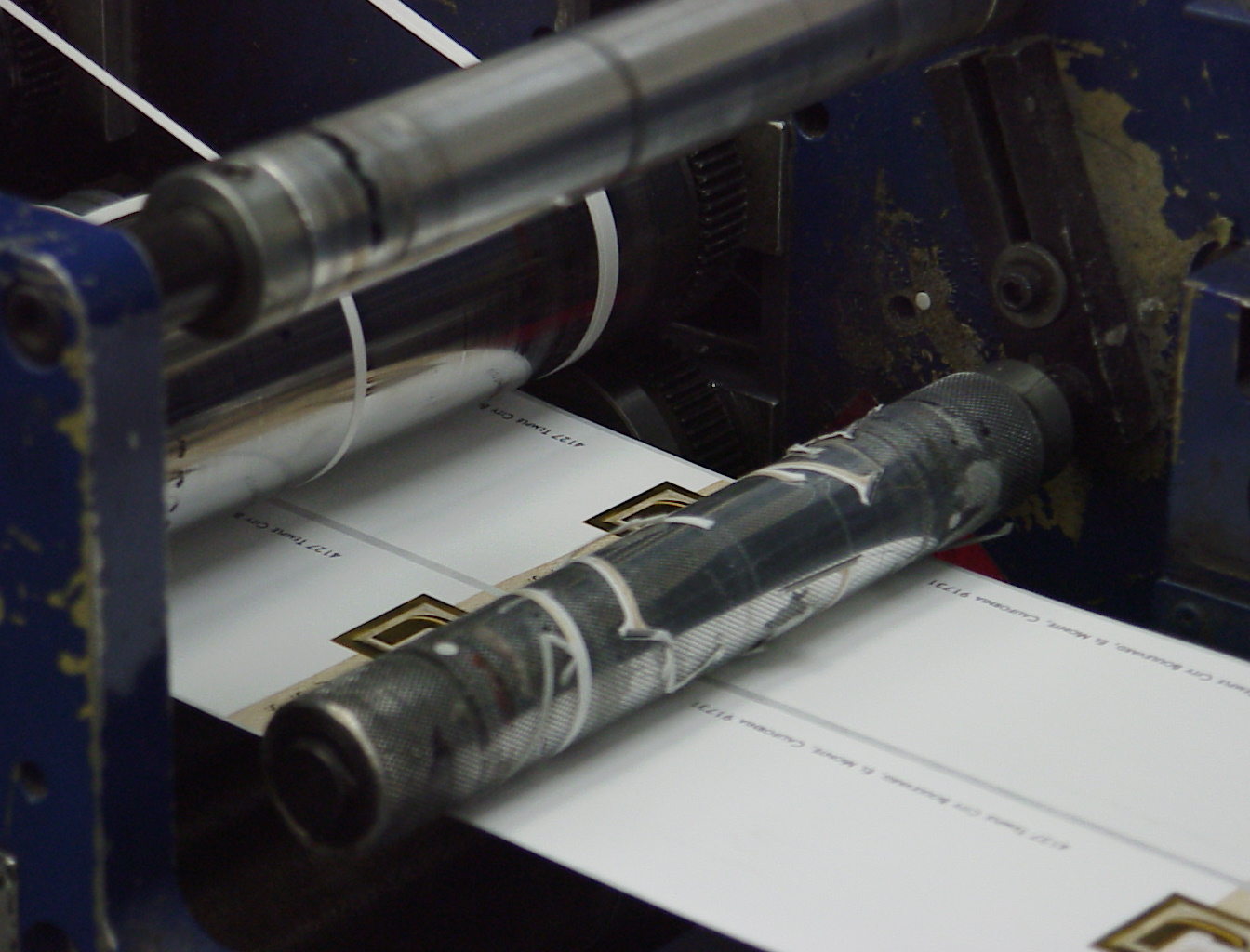

Labels are converted (manufactured) from large rolls of material. This material, which is specified according to usage needs, is fed thorough a web press where ink(s) and features may be applied. |

|

In this photo, a press is applying ink and removing waste material (strip-out). |

|

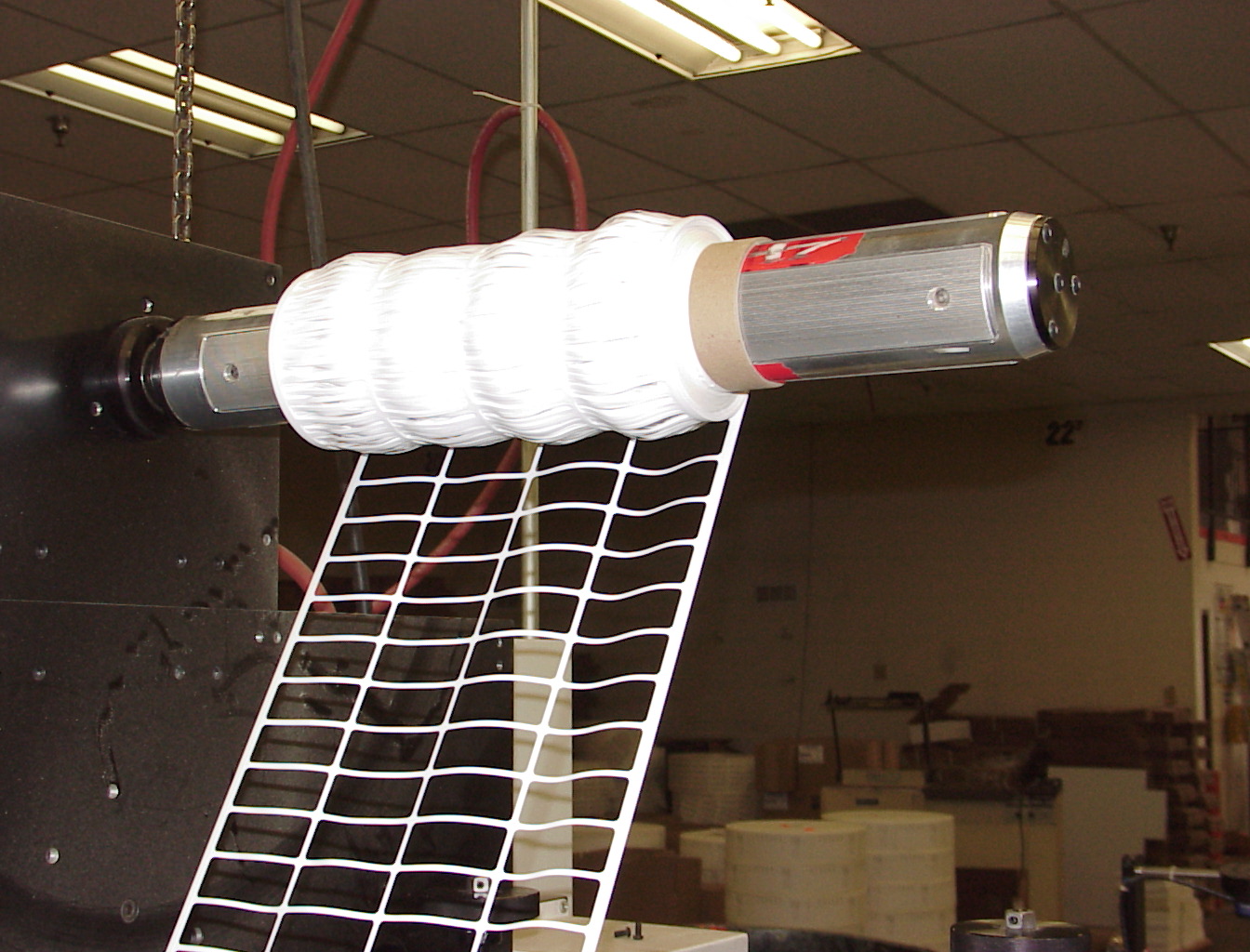

This photo shows a close up of the waste material

(strip-out) being removed and wound for disposal.

The strip-out is the waste created as a result of the die cutting process which creates the individual label. |

|

Inks may be applied, perforations added and strip-out removed all in one operation. |

|

This photo shows a rewinder. This equipment may be used to slit a large roll, after converted, into smaller rolls that will fit an end user's need. |

|

This equipment is creating fan folded finished product. |